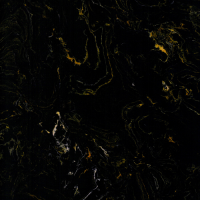

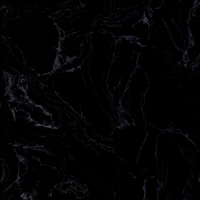

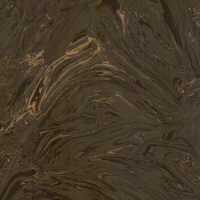

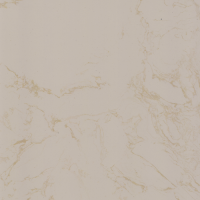

Artificial Marble (Golden Marble)

Artificial Marble (Golden Marble)

Definition of Artificial Marble (GMMC)

The method of manufacturing remains a multi-industry method for industrial marble due to the multiplicity of raw material options used. The Global Marble Company is optimal in that the product is hygienic and environmentally friendly. Its manufacturing is based on 95% natural materials (calcium carbonate stone) and 5% glue material (resin) to give the product strength of cohesion and high hardness with the addition of different color oxides to meet all desire.

Why Artificial Marble (GMMC)

The GMMC Artificial marble product which has been conducted all quality tests according to European standards has been certified by international testing centers SGS approved in physical properties test and THOMAS BELL-WRIGHT used in fire reaction test , Making it the ideal choice for physical and health characteristics and features, including:

- Abrasion resistance: It’s is characterized by the so-called (long-term) and lasts for a long period of time, due to the high price of selling for other short-term products.

- The first choice and the best in kitchens and tables: for the strong resistance to citrus and not affected by oils and grease and citrus fruits such as vinegar and lemon and retain its characteristics and gloss.

- Environmentally friendly product: using 95% natural materials and closed solid surfaces that do not allow virus growth.

- Resistant to spotting and impacting most of the chemicals used in working life.

- Resistant to heat, humidity, decomposition and rot: This is because there are no voids in the product that enable the growth of bacteria or fungus.

- Resistant to absorb water and liquids: A product that is almost absorbent and easy to clean and has no joints and spaces, allowing the collection and accumulation of dirt.

- Fire reaction: Good resistance to fire and does not help if it occurs.

- Non-expandable or deflated: making the best choice for using in hot climate like the Gulf countries, also not affected by cold climate.

- The difficulty of breakage and resistance to high pressure: it’s the best choices for use in the flooring , This is due to the presence of the resin material, which works on the cohesion the components of the product and increase strength and hardness.

- Color stability: Due to its high resistance to liquid absorption.

- Hardness: resistant to scratches.

- Slip-resistance: high resistance in both dry and wet conditions.

Artificial Marble uses (GMMC)

The many of advantages from GMMC making it the first choice in many uses inside houses, kitchen surfaces, bathrooms, public buildings, hospitals, banks, offices, restaurants, marketing centers and many uses that are subject to high efforts, whether climatic factors or personal uses.